We see ourselves as competent partners in accomplishing your tasks. Our many years of experience, know-how and the ongoing further development have made us what we are today: a well-established company that offers plastic sheeting and films for various different sectors.

Our incentive is to always find perfect solutions, which is why we are constantly investing in our modern fleet of machines and our employees. The requirements may constantly differ – consult us. Our claim is always to provide you optimum support.

We produce plastic sheeting and films from the following materials:

– PS – ABS

– ABS/PMMA – ASA

– PP – HDPE

– PETG

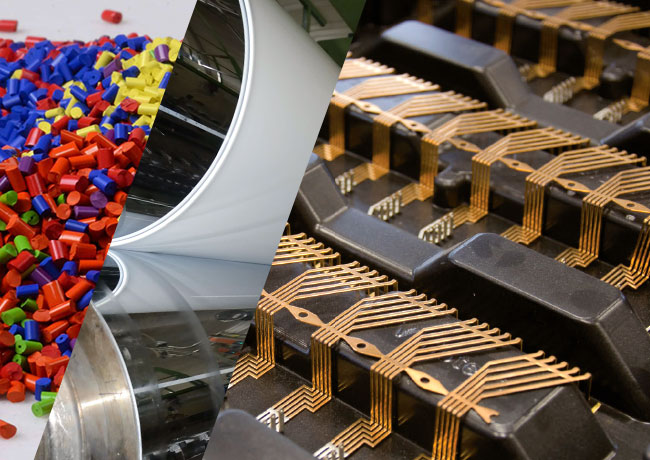

We produce both single-layer and multilayer products on our modern ex-

trusion lines. For films, material thick-

nesses of between 0.30 mm and 3.0 mm are possible. We produce plastic sheeting from a material thickness of 0.30 mm up to 14.00 mm. Our maxi-

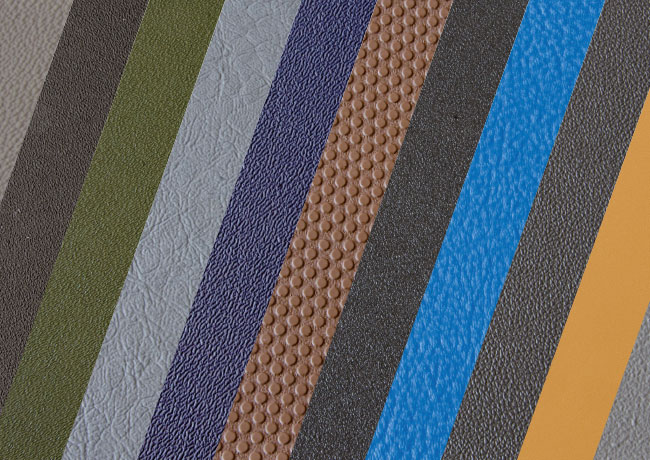

mum production width is 2000 mm. We offer you the widest array of designs for applications with decors and colours.

Production program

We offer you the widest array of designs for applications with textured surfaces.

This begins with very fine and medium textures and ranges to coarse industrial grainings. Leather or negative grainings are also available.

All in all, we have a wide assortment of surfaces with which we can cater for the most diverse applications. Offering the best standard solutions however is just not enough for us.

This is why we also develop specially customised surfaces in conjunction with our customers and find the optimum solution to each individual intended use.

Quality and innovation have been paramount. We consider ourselves reliable, highperformance partners of the plastics processing industry. Our semi-finished products are to be found as final products in the widest array of areas. We are able to perform the most diverse measurements such as for example humidity, melt flow index, glow-wire and conductivity, etc. in our laboratory. We guarantee constantly high, reproducible quality through continuous reception controls on the preliminary products and ongoing in-process controls. The application of our energy management system is in accordance with DIN EN ISO 50001:2011.

– certificate DIN EN ISO 9001/14001

– certificate DIN EN ISO 50001

– certificate UL-746D

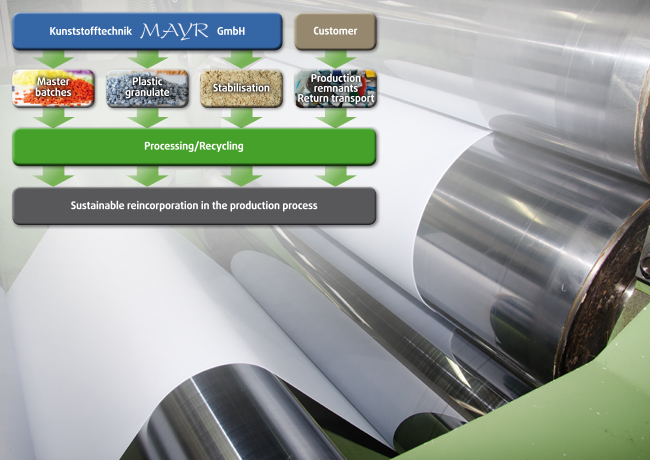

Quality and sustainability play a central role for us. This is why we are not only ISO 9001-certified, but have likewise introduced environment management according to ISO 14001.

Our conscientious approach to all environmental resources has been highlighted by voluntary participation in “EMAS” and the “Bavarian Environmental Pact”.

We save our customers cost-intensive disposal operations by collecting all production wastes with our vehicle fleet, recycling them on our premises and specifically reincorporating them in the production process.

Requirements for plastic components are many and varied and are not always directly apparent.

Characteristics such as for example:

– Deep drawing capability

– Flame protection

– Abrasion-resistance

– Sealability

– Lamination

– Discharge ability

– Stamping compatibility

– Elasticity

– Biodegradability

– Regeneration

are often indispensable and necessary for your successful final product. We use our experience to your advantage.